Brunvoll is offering conversion kits to enable its range of propulsion and manoeuvring thrusters to be retrofitted with a split lubrication system for use with Environmental Acceptable Lubricants (EALs).

Brunvoll’s split lubrication system, ensures compliance with US Vessel General Permit (VGP) requirements while allowing continued use of cost-effective mineral oil. The kits are said to be environmentally friendly, and VGP approved.

Where applicable, the EAL conversion includes a general upgrade of the pitch mechanism, ensuring a longer lifetime and reduced wear. The conversion is a one-time investment with low maintenance costs and low technical risk. It enables the use of low-cost standard lubricants instead of replacing the whole lubrication system with EAL.

The US Environmental Protection Agency (EPA) VGP, as revided in 2013, establishes requirements for 27 specific types of incidental discharges from vessels. All vessels covered under the VGP must use EALs in all oil-to-sea interfaces unless technically infeasible. Oil-to-sea interfaces include any mechanical or other equipment on board a vessel where seals or surfaces may release quantities of oil and are subject to immersion in water. EALs are lubricants that are described as being ‘biodegradable’ and ‘minimally-toxic’ and ‘not bio-accumulative’ as defined in the VGP.

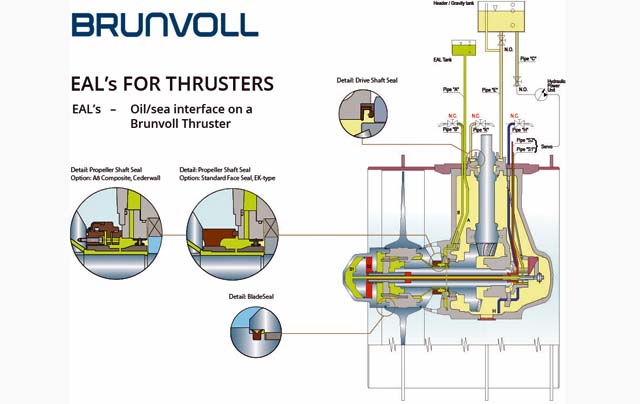

Based on these VGP requirements, Brunvoll has developed, tested, and implemented an EAL solution that is technically feasible for most thrusters within the product range. Brunvoll’s split oil system applies EAL in all direct oil-to-sea interfaces and conventional mineral oil in the gearbox. In Brunvoll thrusters, oil-to-sea interfaces pertain to the propeller hub with blade seals and the propeller shaft main seal. The gearbox reservoir, containing mineral oil, is sealed with static seals, ensuring at least two barriers between the sea and the mineral oil.

The advantage claimed for this solution lies in its ability to meet VGP requirements and the associated environmental benefits, while continuing to employ reliable and well-established mineral oil in the gearbox. EALs, though often touted as fully functional gear oils, are relatively new to the market, with limited data on their long-term effects on gears, bearings, and paint. Moreover, there are several limitations to consider when using an EAL as a gear oil, including local temperature and water contamination. By adopting Brunvoll’s split lubrication approach, the company believes that the technical risk of major breakdowns is minimised.