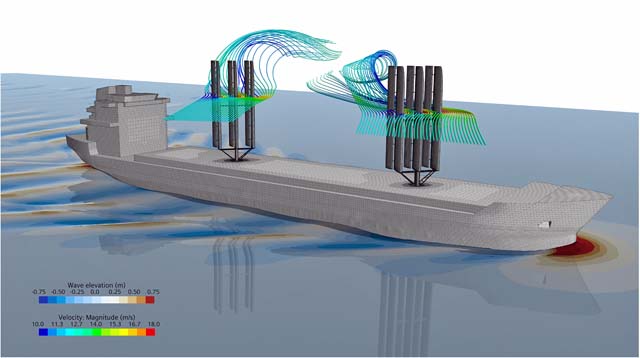

UK consultancy Cape Horn Engineering has developed a simulation workflow to directly compare the efficiency of wind assisted propulsion (WASP) devices, taking into account the most important effects of adding wings, Flettner rotors or any other type of wind powered device to a vessel.

Both the water flow experienced by the hull at a given vessel speed and the air flow experienced by the hull top sides, superstructure and WASP devices, at a certain wind speed and direction, are modelled simultaneously in a single simulation.

The wind conditions above the water surface are modelled with an accurate wind profile taking into account the atmospheric boundary layer wind gradient, which results in a variable wind speed and direction at different heights. In the simulations, the vessel is sailing at constant speed, and an actuator disk models the effect of the propeller. Depending on the vessel resistance and the amount of thrust generated by the WASP devices, the actuator or virtual disc model determines the propeller RPM and propeller torque and thus delivered power.

The simulation further considers the deformation of the free surface of waves generated by the vessel, the dynamic sinkage and trim, the drift or leeway angle, the heel angle and the rudder angle to keep a constant course. Thus, 6 degrees-of-freedom are considered. The wind forces on the hull, superstructure and WASP devices induce the drift and heel angles, with the rudder angle changing during the simulation with the application of a PID controller, balancing the yaw moment of the whole system. The vessel speed is constant with the propeller RPM, and therefore torque and power, responding to the drag of the hull and thrust from the WASP device. The thrust produced by the propeller balances the degree-of-freedom in direction of travel.

When the simulation converges to a quasi-steady solution, different WASP configurations can be directly compared by comparing the delivered power of the propeller and thus a direct measure of the fuel (and emissions) saving potential can be assessed.