Australia-based company InterContinental Energy, specialising in large-scale green hydrogen development, has announced its patented P2(H2)Node system for hydrogen production, aimed at meeting the projected demand for green hydrogen from hard-to-abate industries such as ocean shipping.

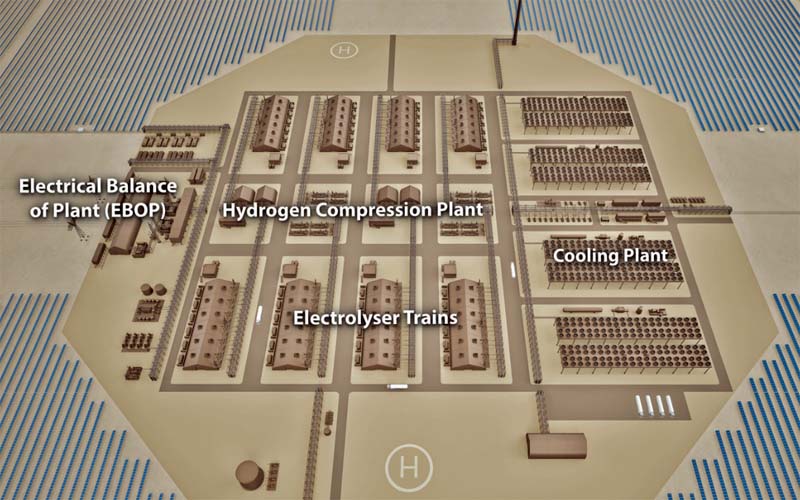

Designed in Australia after four years of innovation and engineering,InterContinental Energy’s solution is said to cut costs, boost efficiency, and allow for the scaling of giga-scale green hydrogen production. The company expects that its P2(H2)Node standardised architecture will streamline the green hydrogen industry by replacing bespoke projects with a uniform approach, believing that removing complexity and increasing repeatability can ensure all projects will have access to the lowest cost of production. Conventional centralised models require expensive electricity transmission, leading to energy losses and inefficiencies. The patented P2(H2)Node system is said to flip this model by co-locating giga-scale hydrogen production with wind and solar farms, ensuring power is used where it is generated.

The system is estimated to lower production costs by 10%-20%, which will enable faster large-scale hydrogen adoption for industries such as green shipping fuels.

Key advantages claimed for the P2(H2)Node architecture include:

- Up to 10% lower Capex through standardisation, modularity, reduced electrical infrastructure and reduced storage requirements

- Up to 10% more efficiency through design optimisation and elimination of very high voltage power equipment

- Built-in energy storage to allow for more consistent flow delivery to customers via line packing of hydrogen pipelines

The P2(H2)Node architecture is the backbone of Australia’s Western Green Energy Hub (WGEH). Designed to produce and export green hydrogen and ammonia, WGEH boasts a planned 70GW renewable energy capacity – positioning it as the world’s largest and most cost-efficient green hydrogen hub. With the support of newly announced Australian Government hydrogen incentives, WGEH is projected to drive down production costs for green ammonia below US$ 650/t, unlocking investment opportunities and job creation.

With demand for green hydrogen set to surge, the P2(H2)Node system is considered to offer a global, scalable, cost-efficient model for providing green molecules to the hard to decarbonise heavy industry and transport sectors.

Alexander Tancock, CEO InterContinental Energy, said: “We are proud that our team in Perth has developed this globally significant technology. The P2(H2)Node architecture is a breakthrough in clean hydrogen production. By eliminating transmission losses and leveraging a modular approach, we are making green hydrogen cost-competitive at scale for the planet. This technology comes at a time when Australia is poised to become a global leader in e-fuels and green iron.”

InterContinental Energy is working with global partners to deploy the P2(H2)Node architecture and fast-track industrial decarbonisation. As the hydrogen market grows, this solution is expected to drive efficiency, scale, and cost reductions worldwide.

Image: The patented P2(H2)Node architecture (source: InterContinental Energy)