Swiss marine power company WinGD has introduced its first high-pressure LNG dual-fuel engine, the X-DF-HP, developed specifically for the demanding operating profiles of ultra-large container vessels (ULCVs).

The new engine is said to arrive at a pivotal moment for shipowners navigating the energy transition, with the IMO’s Net Zero Framework currently paused and the prospect of regional regulation becoming increasingly fragmented. WinGD believes that, as a result, interest in LNG-fuelled tonnage is continuing to accelerate.

Available in X82 and X92 bore sizes, the X-DF-HP is tailored to the scale, speed and load requirements of the ULCV sector, with first deliveries planned for 2028. Based on comparisons between the efficiency of WinGD’s established diesel engines and similar dual-fuel designs, the high-pressure dual-fuel concept is anticipated to deliver improved efficiency.

Benny Hilström, VP Market Development, WinGD. said: “Large container vessels present a unique propulsion challenge. They demand immense power, exceptional efficiency and long-term fuel flexibility. With the X-DF-HP, we are providing operators with a purpose-built solution for the most power-hungry vessels, offering uncompromised, trouble-free propulsion.”

Available with the same auxiliary system requirements—such as fuel supply pressure—as other recognised engine concepts, it supports straightforward installation for shipyards and provides a practical, future-ready option for vessel owners. Achieving Tier III compliance in both gas and diesel modes using only a standard SCR, the company claims that the X-DF-HP offers operators a powerful, space-efficient and future-ready choice for the most demanding ULCVs.

Sebastian Hensel, WinGD VP R&D, said: “The X-DF-HP is built on the high-pressure Diesel X92-B engine platform that has already proven itself as one of the most efficient and reliable large-bore solutions in the container segment. Building on our long-standing diesel engine expertise and our deep experience in LNG dual-fuel technology, we’ve developed the X-DF-HP. Our tests and simulations show the X-DF-HP will deliver a clear step up in fuel efficiency and GHG performance compared to existing high-pressure dual-fuel engines on the market.”

The X-DF-HP builds on more than a century of high-pressure Diesel cycle expertise and dual-fuel innovation at WinGD. It joins the company’s high-pressure, multi-fuel portfolio, which includes the methanol/ethanol-capable X-DF-M/E and ammonia-fuelled X-DF-A engines. This provides operators with a fuel-flexible platform, with established engines such as the X92-B now able to be retrofitted for high-pressure LNG, methanol, ethanol, or ammonia as fuel pathways evolve.

With LNG providing FuelEU Maritime compliance well into the next decade, and uncertainty remaining around future IMO requirements, LNG continues to offer a cost-competitive, low-risk route to fleet decarbonisation. WinGD’s X-DF (low pressure) and X-DF-HP engines are fully compatible with renewable methane blends, enabling operators to progress towards lower-carbon operations without extensive mechanical modifications or the high retrofitting costs typically associated with emerging fuels.

Hilström concluded: “For ultra-large container vessels choosing LNG as their pathway to net zero, the X-DF-HP is the most cost-effective option. For all other vessels, the low-pressure X-DF platform continues to deliver the best lifecycle economics. Together, these propulsion options give vessel owners and operators complete confidence in selecting LNG—and WinGD—for the energy transition of their fleets.”

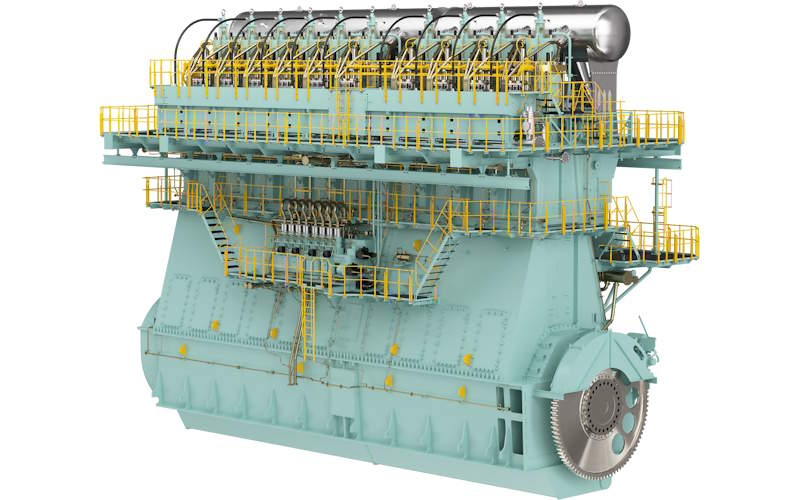

Image: WinGD X-DF-HP engine (credit: WinGD)